Products

BISAI

Lay-sheet, sampled sheet inspection sysetm

Sheet fed offset printing

Offset rotary press

Packages

Data vs sheet inspection to find the defects including thin scratches and missing letters

Many aspects of the software is automated. And the design concept of the UI is simple.

Anybody can use the machine in minimum training with the assistance of the software.

Features

400dpi ultra-high resolution

BISAI’s resolution is 400dpi, approximately 0.06mm×0.06mm per pixel.

Being able to scan thin scratches and small letters.

By using the camera as the scanning equipment, it has ability to adjust to range of thickness.

Automatical adjustment of color among data and sheet

Data and scanned image, by its nature, always has color differences.

BISAI can adjust this difference automatically.

Algorythm specialized in detecting plate scratch

One of the important inspection for lay sheet is, to find plate anomaly.

BISAI has special algorythm to find thin scratches.

By this feature, user do not need to set overly strict inspection parameter to detect such thin and small scratches.

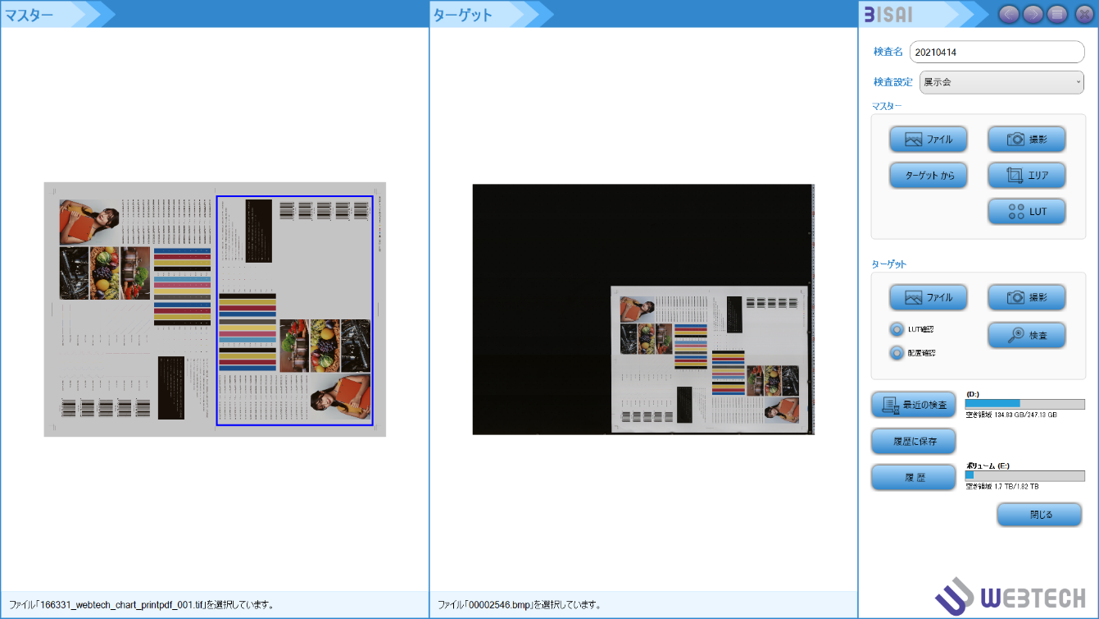

Simple and easy UI

For the human resource matter, it is important that inspection system can be operated by anybody.

BISAI’s software is very easy and simple.

Inspection result can reached by few clicks.

Also, the software has a mode to show step-by-step instruction to the operator.

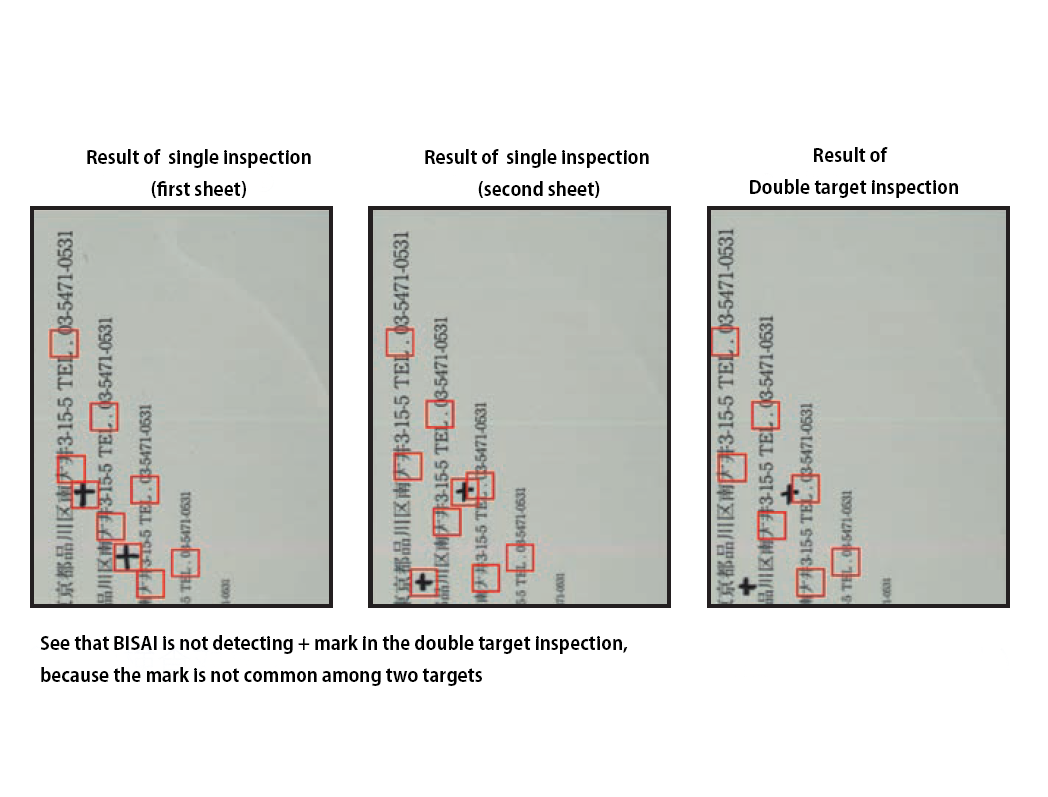

Double target inspection

When using papers such as recycled paper, paper will defer with the data everywhere because of fiber residue and other objects.

Normally, inspection system deals with such harmless differences by loosening the inspection parameter, but by doing so, actual defect with similar size and density will also be undetected.

In order to handle such dilemma, BISAI has unique function to inspect two targets per one master.

By only showing defects “common to both targets”, BISAI can ignore harmless diffrences and only show repeating defects which affects the production.

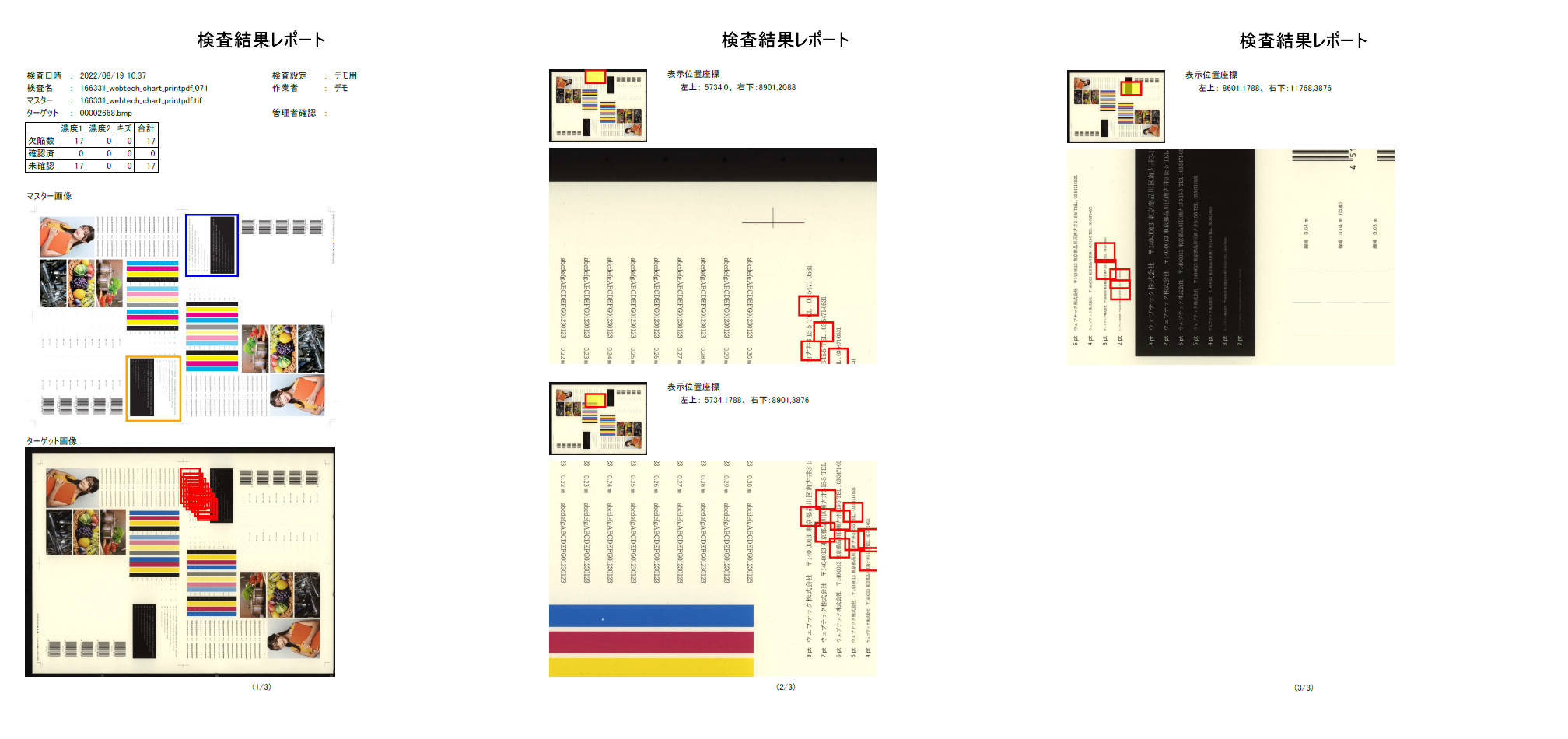

Report generate function

BISAI can generate report of inspection result by one click.

It can be used as, for example, to ensure the traceability, and in the discussion with the customer.