Products

SENSAI

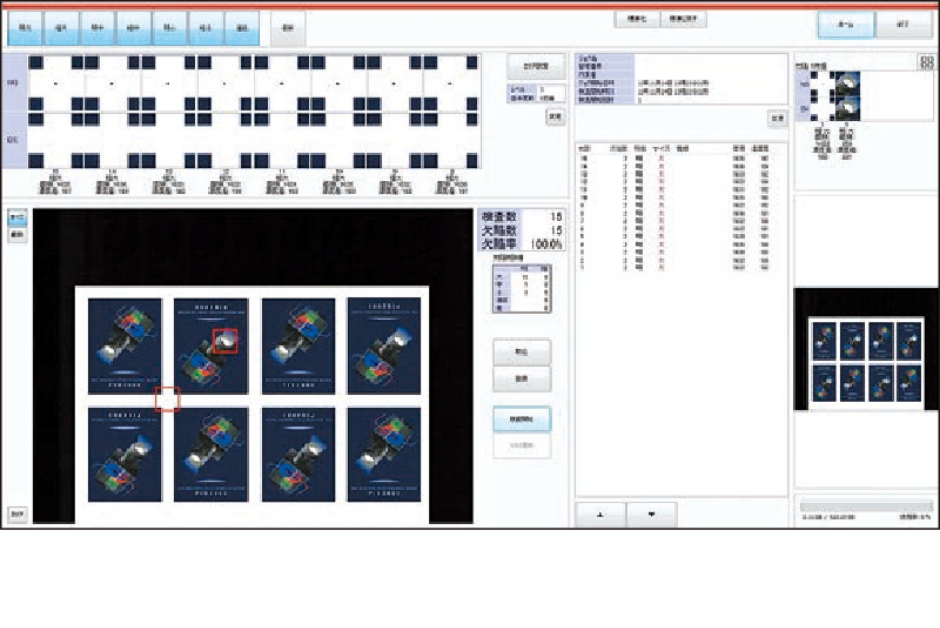

Inline insepction for sheet-fed printings

Sheet fed offset printing

Packages

The total solution for inspection, loss control, and traceability.

By using 4K to 8K camera, it can detect various print defects.

The Harware

High contrast 4096bit digital color camera

Our SENSAI comes with 4096bit digital camera with 3CMOS method sensor.

By its high resolution and sensitivity, it can scan small defect such as missing or deformed letter, color anomaly, and so on.

Directional lighting system

Our lighting technologies, enables the inspection machine to inspect regardless of the paper used.

By installing optional light, inspection of metalized papers.

Unique sheet stabilizing system

Applying the aerodynamics, the sheets will be highly stabilized.

Optimization of the airflow and power, SENSAI can inspect thin to thick papers.

Multi touch display

Simple UI with multi touch display, the operation of the inspection system is very easy.

Touch panel for machine control

Machine control such as airflow of SSS, buzzer, tape inserter, numbering IJP, can simply be done from the touch panel.

External switch

External switch installed nearby the delivery unit enables the operator to control the inspection software without leaving the delivery unit.

Numbering IJP (optional)

Optional inkjet printer lets the system to print serial code to the margin of the sheet.

The tracing of the defected sheet becomes easier and certain.

Rejector (optional)

Automatic rejector can separate the defected sheet from the OK sheet.

The Software

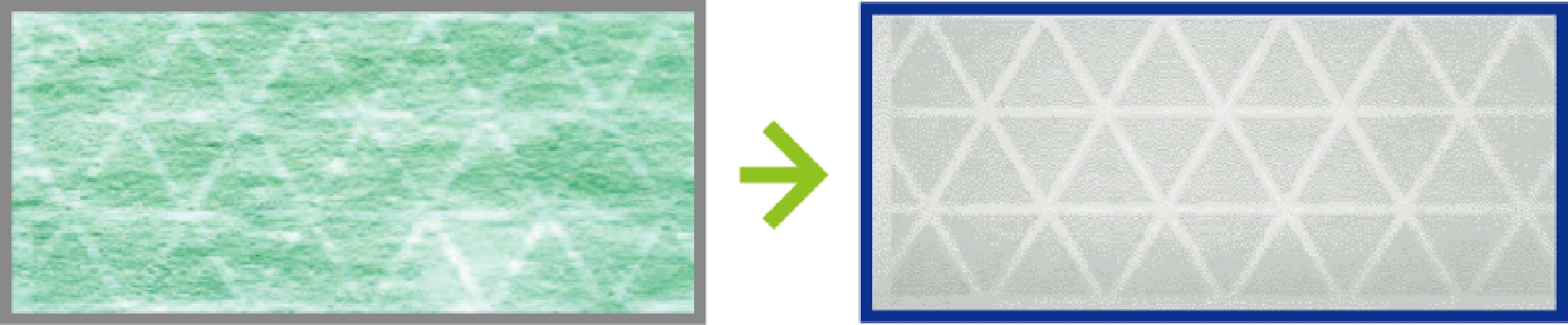

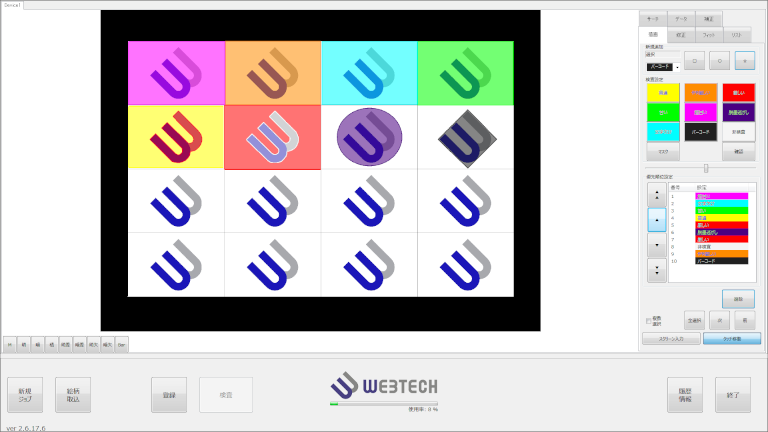

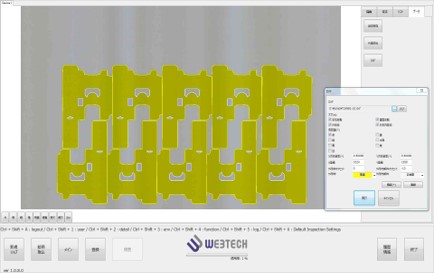

Multi parameter and multi area

SENSAI can set multiple inspection areas to one sheet, each having different inspection parameter.

Maximum 9 different parameters can be pre-set, each being expressed by different color.

-1.png)

Defect treatment

SENSAI can treat each defected sheet differently depending on the size of the defect.

For example;

・Big size defect=buzzer meolody 1, middle size= buzzer melody 2, small size=no buzzer

・Big size defect=insert tape + buzzer, middle size=no tape + buzzer, small size=only show on screen

…etc

Search function (optional)

SENSAI can search inspection area.

In impositioned design, it is burden some to draw area onto every imposed images.

By installing this function, user only has to draw an area to one imposed image,

and SENSAI will find the rest from the sheet.

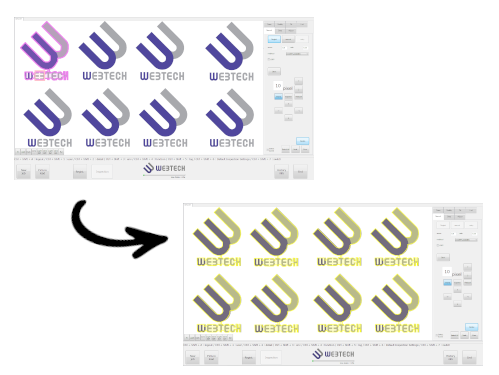

Fit function (optional)

Fit function enables the user to “fit” the area to the artwork.

By drawing a area which abstractly surrounds the artwork, SENSAI will find artwork inside,

and fits the inspection area to it.

AB system for PP/PET (optional)

Enables to inspect PP/PET sheets printed by double sized cylinder.

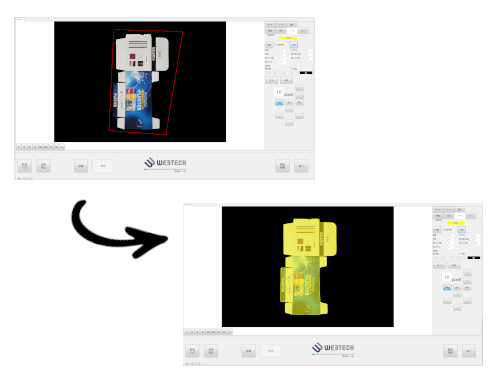

DXF data loading function (optional)

By loading the DXF data, SENSAI can use it as a reference and semi-automatically draw inspection area.