Products

PLUSTER Top-feed model

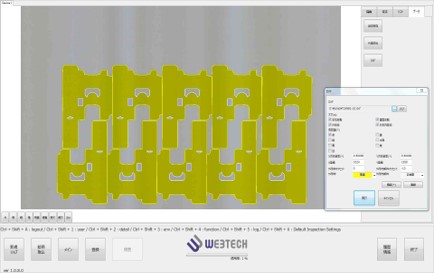

Offline package inspection system

Sheet fed offset printing

Packages

The convey machine can be customized to meet the needs of the users.

Conveyer example

Top-feed

The top feed mechanism with stable feeding and no damage to the product.

Delivery with automatic sideway conveyence

Delivery can be customized to have the inspected OK products being automatically stacked and conveyed aside, in order to let the machine operate without stopping to remove the inspected products.

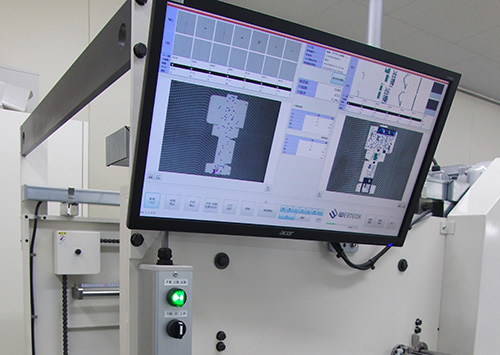

Delivery part side moniter

Can install moniter in the delivery section.

Operator do not need to leave the delivery unit to check the inspection result.

Auto NG reject

Defected products are automatically rejected.

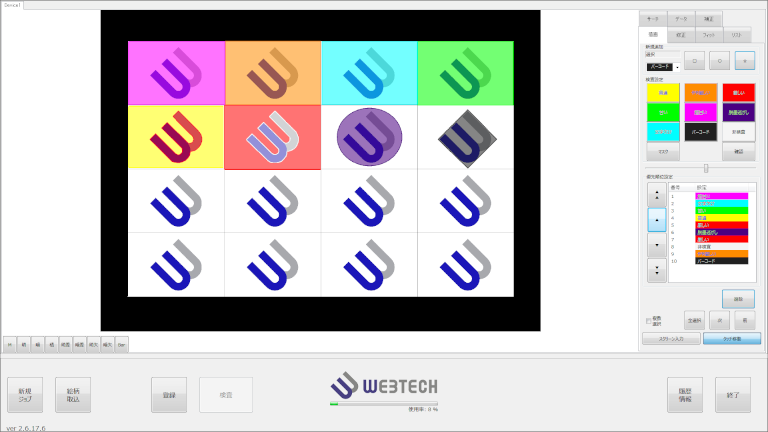

Software Feature

SENSAI tuned for offline inspection

The inspection software installed is SENSAI, with features for offline inspection.

Fit function (optional)

Fit function enables the user to “fit” the area to the artwork.

By drawing a area which abstractly surrounds the artwork, SENSAI will find artwork inside,

and fits the inspection area to it.

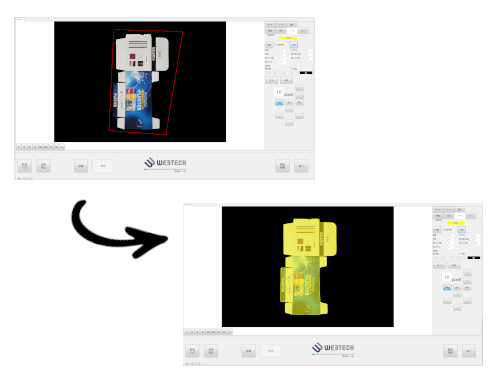

DXF data loading function (optional)

By loading the DXF data, SENSAI can use it as a reference and semi-automatically draw inspection area.