Products

SENSAI-CP type.c

Corrudator inspection syste,

Cardboad production

Not only inspecting, but supports the defected sheet extract.

Features

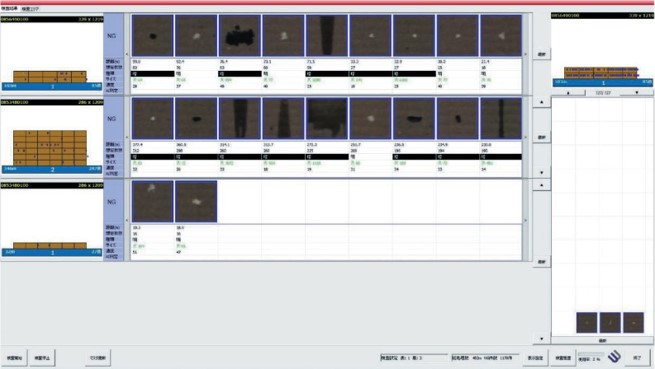

Unique UI to support the defected sheet locating

During the corrugation, corrugated sheet will be palletized.

The problem is, these pallets is not divided periodically, but by the manual operation.

So, normally, inspection system loses track of defected sheet. Which pallet? Where in the pallet?

Our UI, by receiving signal from the corrugator, tracks the defected sheet with the pallet division information.

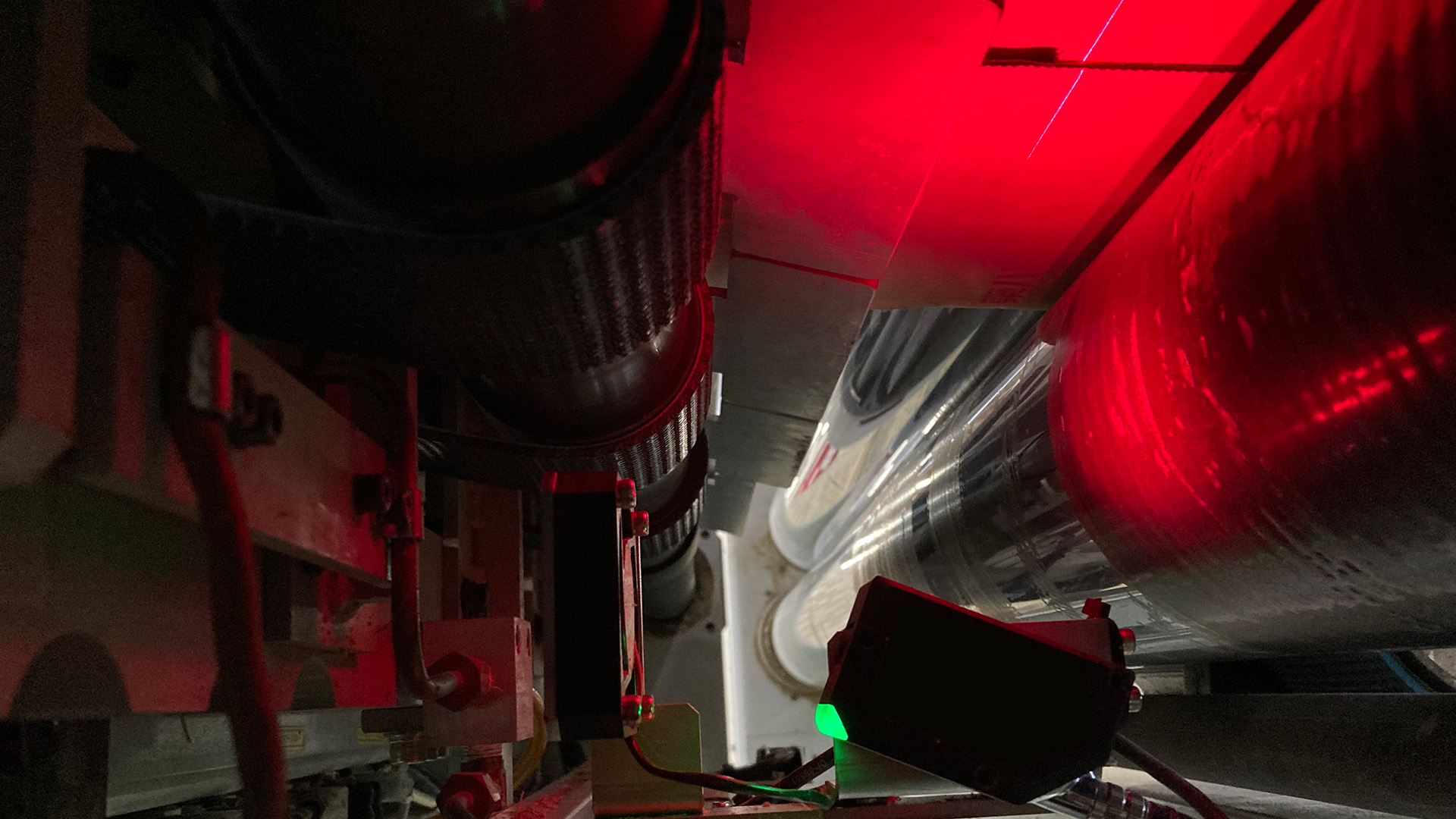

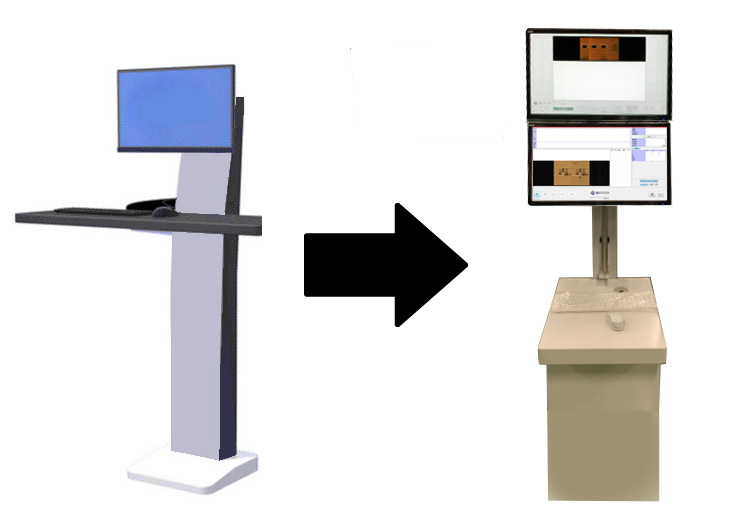

Installable after the slitter scorer

Inspection system can be installed after the slitter scorer.

Allowing inspection being

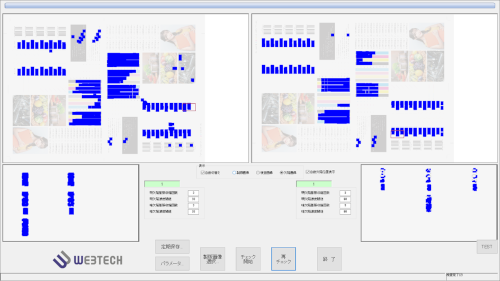

Data vs sheet inspection

Our inspection system can use design data (PDF/TIFF) as a OK sheet standard.

This feature is mainly targeted to see the plate related problem.

Linkage with the production machine

Our inspection system can receive information from the production machine.

For example;

Paper type

Work name

Work size

Number of colors used

Production start

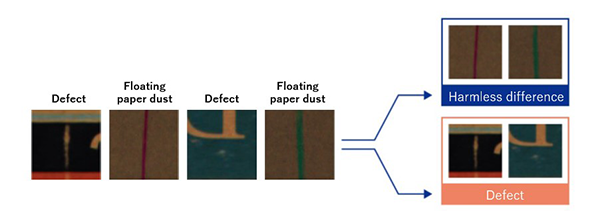

Inspection reinforcement by AI

In the cardboard production, there is always a floating paper dust in the factory.

This floating paper dust will be randomly appear in the scanned image.

Our AI software will differentiate this paper dust from actual defect.